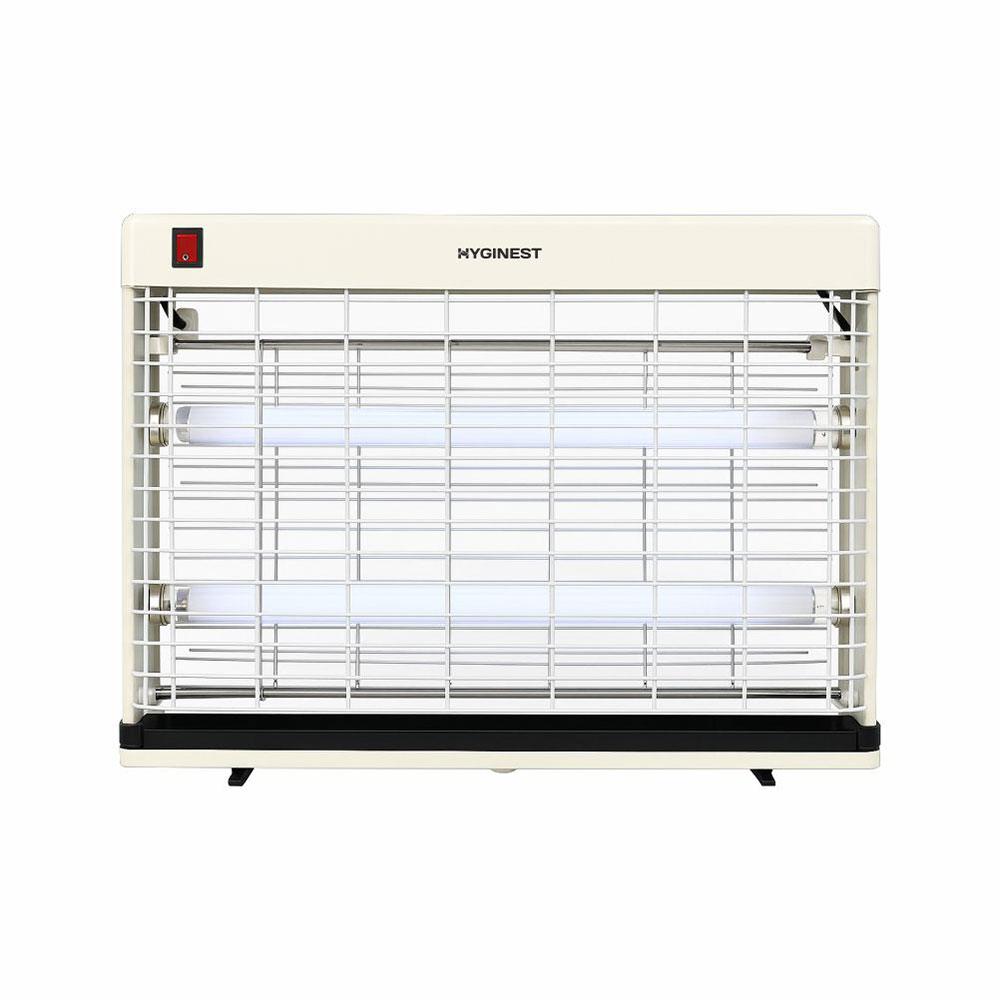

Model: HFCM93 MS Powder Cotad Body

Model: HFCM94S SS202 Body

Model: HFCM95S SS304 Body

Enhance Comfort & Energy Efficiency

Our high-performance Fly Catcher offers a reliable and hygienic solution for controlling flying insects in sensitive environments such as commercial kitchens, hospitals, food processing units, and institutional spaces.

| S ize | 25" (L) X 7" (D) X 18" (H) |

|---|---|

| Tube | 18W Actinic BL UVA Lamp |

| Choke/ Driver | 20 W Electronics UV Choke (For Individual Tubes) |

| Electrical Rati ng | 230 V / 50Hz |

| Transformer Voltage | 2.4Kv |

| Output Catch Specification | One Catchment Tray |

| Weight | 4.5Kg. Approx |

| Technology | Ultra Voilet Based Attraction |

| Effectiveness | Based Upon Light Intensity (Approx 300-400Sqft) |

| Mounting Position | Free Style / Wall Mounted / Hanging Type |

| Other Specifications | Aluminum Wire Grid With Teflon Separators |

| Glass Fuse For Safety | Illuminated Rocker Switch For ON/ OFF / ISI Powder Cord |

Product Toolkit

Fly Killer & Catcher Machine – Frequently Asked Questions (FAQs)

A fly killer uses high-voltage electric grids to instantly kill flying insects, while a fly catcher (or fly trap) typically uses UV light and glue boards to trap flies without noise or smell.

An electric fly killer machine uses UV light to attract flies and other flying insects. Once they come close, they are electrocuted by a high-voltage grid, providing effective fly control in indoor spaces.

Yes, industrial fly killers with glue board or fly catcher machines are ideal for food processing units, kitchens, and pharma industries, as they prevent insect contamination and ensure hygiene compliance (GMP/HACCP).

Install the fly killer unit:

- At a height of 6–7 feet

- Away from windows and strong airflow

- Near entry points or areas prone to flies

Avoid placing directly above food or workstations.

No, fly catcher machines with glue boards operate silently and do not produce any smell, making them suitable for offices, clinics, and retail spaces.

- Use electric fly killer for high-density fly zones (e.g., garbage area, production unit)

- Use glue board fly catcher in sensitive zones (kitchen, pharma, food packing) where hygiene is critical and noise/sparks are not allowed.

UV insect traps are highly effective in attracting flies, mosquitoes, and moths. They provide chemical-free, eco-friendly fly control suitable for both residential and commercial use.

- Clean the machine weekly

- Replace UV lamps every 8–12 months

- For glue board models, replace the glue pads every 15–30 days

- Always disconnect power before cleaning

A high-quality commercial fly catcher or industrial fly killer typically lasts 3–5 years, with regular maintenance and timely replacement of lamps and glue boards.

Yes, restaurant fly killers or UV fly catchers with glue traps are safe, quiet, and hygienic. They help maintain fly-free dining and kitchen areas, enhancing your brand image and customer satisfaction.

Use a glue board fly catcher with shatterproof UV tubes and stainless steel housing. This ensures compliance with GMP and ISO standards and avoids insect fragments in the air.

Most UV fly killer machines consume between 15W to 60W, depending on the number of tubes. They are energy-efficient and low-maintenance.

Yes, UV fly killers work in both day and night conditions. However, effectiveness improves in dim lighting or shaded areas where the UV light is more visible to insects.

Ideal placements include:

- Food processing areas

- Canteens and cafeterias

- Waste disposal zones

- Hotel kitchens and corridors

- Packaging and pharmaceutical rooms

Absolutely. Compact fly catcher machines are available for home, office, and clinics. They are chemical-free, silent, and effective against common houseflies and gnats.